How to Perfect a 4 Corner Grain Match

Flawless joints are just a few steps away

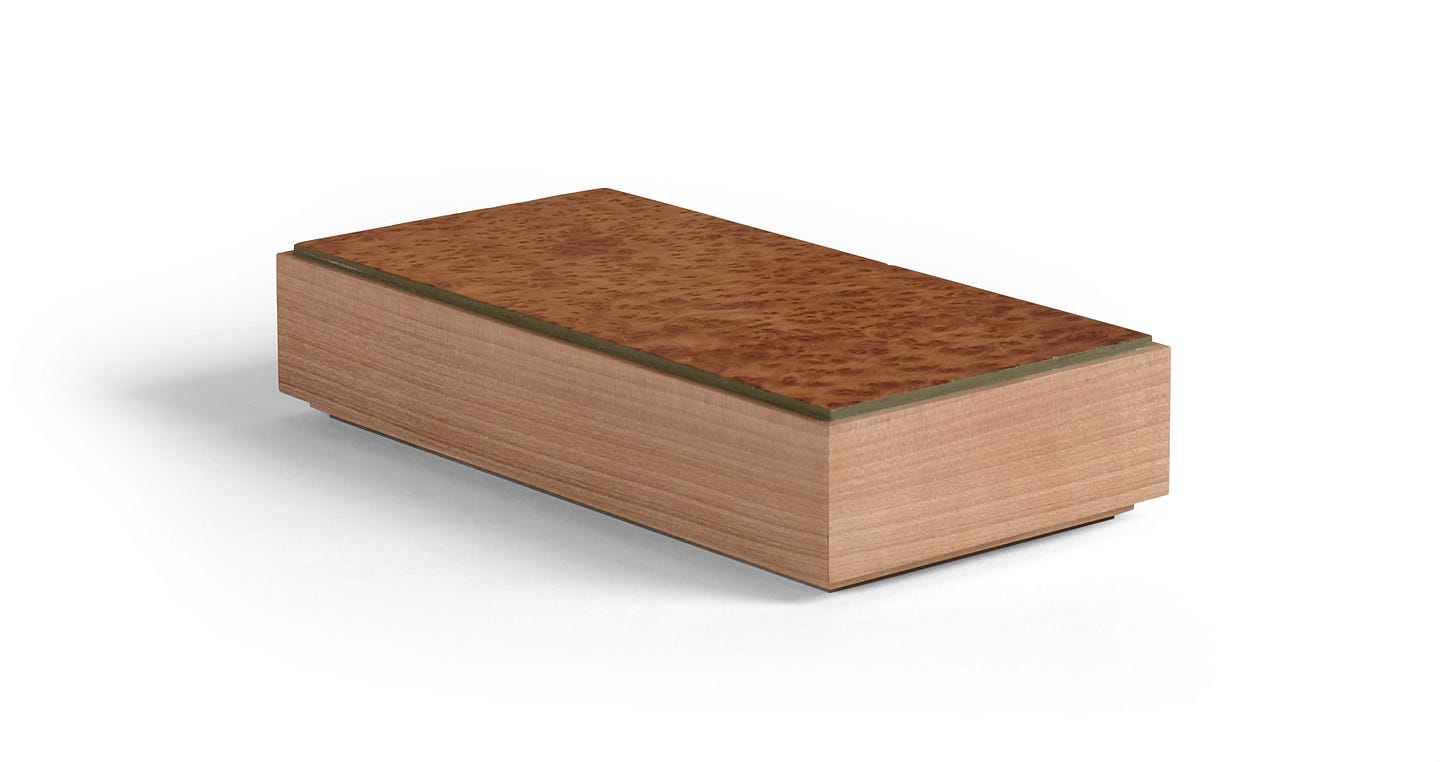

Some furniture has “jpeg beauty” because it looks great in a photo, or from a short distance, but when you look closely, flaws emerge. Perhaps there are gaps in the joints or the finish is bumpy. Maybe there are machining marks still present, or the curves are not fair. I think we all strive for furniture (and boxes) that are better than jpeg quality. To get there, you must pay attention to details. One detail that is often overlooked is grain. I’ve written about the importance of selecting material with grain that improves the beauty of what’s being made, and now I am going to dive further into how you can use and manipulate grain to make your mitered boxes even more attractive than they already are.

Before I explain how to improve the grain at all four corners of a mitered box, I should remind you of two related posts I’ve written. The first is about how the cut of a board (flat, rift, quarter) affects a bookmatch, and the second explains how to improve a bookmatch with smart milling, because a four corner grain match is just a type of bookmatch.

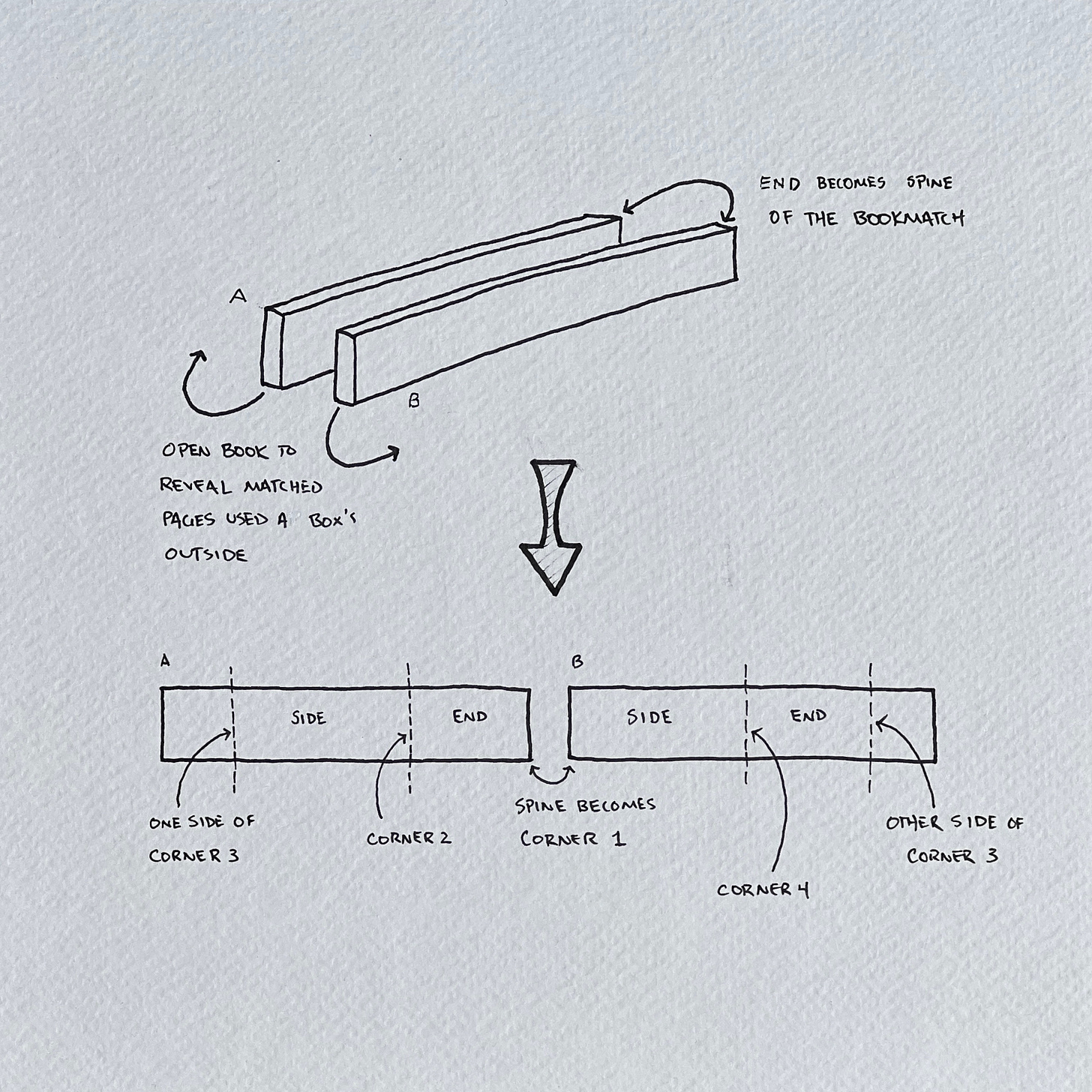

One more thing before we get to the all-important details. Here is a quick explanation of how a four corner match is created. You start with a board that’s roughly three times thicker than the thickness of the box’s sides. Cut that board into two new boards and mill them to final thickness. Then cut the sides in the manner shown below. What I am explaining today is how to improve the grain match at joints 1 and 3 in the drawing.